Written by Riley Collins //

Big business has long been synonymous with oil spills, environmental degradation, and the overall promotion of a system that emphasizes quarterly profit above all else. However, many corporations are now turning a new leaf and using their size to exert influence across the economy by improving the environmental sustainability of their supply chains. The scale and quickness with which large businesses can act makes this an area that is extremely promising in reducing environmental degradation globally.

It is important to understand what exactly the term “supply chain” consists of in order to understand how to create positive impacts within it. A supply chain envelopes the distinct areas of logistics, operations, transportation, and production, with the overall goal of delivering the right product, at the right time, to the right place, at the least cost. Notably, the majority of companies’ social and environmental footprints occur in this space. A study by McKinsey details that a typical consumer company’s supply chain accounts for over 80% of its greenhouse gas (GHG) emissions and 90% of its local environmental impact. Sustainability is a “pre-competitive issue” for companies, meaning that they often strive to make their supply chains more sustainable regardless of consumer pressure, because sustainability and supply chains work in tandem toward many of the same goals. The best supply chains are the most efficient ones since efficiency means cost savings, as well as less energy, water, and land consumption. Companies’ desire for efficiency lends itself to creating “lean” supply chains, which are both greener and more cost-effective.

One of the most important things to note when discussing this space is that ranking companies by “sustainability” metrics often results in different outcomes depending on the group conducting the study. Even the most well-known and oft-cited Corporate Social Responsibility (CSR) rankings, such as those done by Newsweek, Forbes, and CSR Magazine have little similarity in their outcomes — in one study, just 12% of companies appeared on all three lists. This is because each rating agency’s criteria and methodology for determining what makes a company more or less sustainable differs: they may ask companies to submit different inputs, use different weighting percentages for categories, or publish different outputs than their counterparts. Not only do third-party sustainability rankings differ, but companies also vary greatly in the way they measure sustainability. For example, how far a firm chooses to “scope” their emissions, and how lenient they are on themselves internally during data collection, affect the results of both external and internal CSR reports. For sustainability to be improved effectively, transparency and consistency must be achieved across rankings and company metrics. Fortunately, standardization of these processes has been increasing with the assistance of organizations like the Sustainability Accounting Standards Board. This will provide clearer analytical insights into sustainability initiatives, allowing best practices to be shared more efficiently, and investors to make better decisions.

Global supply chains are tangential to many large social problems. For example, the use of child labor has been a concern in many low-income countries. However, improvements to global supply chains are often difficult to enforce because they are large, badly policed, and decentralized. For instance, Nike was exposed for using child labor and pushed to eliminate this from its supply chain, but they found it was nearly impossible to remove these practices directly. Further, even if companies do manage to do some good, it can still have unintended consequences — eliminating child labor may rid a family of an opportunity to earn essential income. Although Nike has undertaken efforts to improve, they still have lots of work to do. At the end of the day, though, addressing the root cause of such problems often requires “raising the floor” in these locations by reducing corruption and improving their economies, something which is out of the hands of any individual company.

They also face environmental challenges of similar scale and complexity. For example, 400 consumer goods companies passed a resolution to achieve net zero deforestation by 2020 in their supply chains, yet only 21 of those firms made any quantitative progress on their commitments, and even successful remedies may harm local economies and biodiversity. However, sustainability problems differ somewhat from social problems, in that sustainability initiatives often improve company performance, unlock new markets, and reduce long-term risk. Doing the right thing in this particular case is entirely consistent with generating economic value, and more companies are beginning to seriously improve the carbon footprint of their operations and supply chains as a result. A 2019 report conducted by the Carbon Disclosure Project outlined over 5,500 suppliers who enacted sustainable practices, resulting in financial savings of $19.3 billion per year. Sustainability efforts can result in immediate cost savings by improving energy efficiency, using less fuel, reducing waste, and using less packaging. In the long-term, sustainability ensures supply chain resiliency and profitability through risk mitigation and by continuing to decrease operating costs. Other benefits such as increased employee engagement and brand enhancement are also realized. Further, as big businesses embrace sustainability, these best practices are cascaded down to their suppliers, many of them small businesses, making those companies more efficient and profitable.

One common criticism of corporate sustainability is that efforts are nothing more than “greenwashing.” This is where companies market themselves as being sustainable without actually investing significant time and money in implementing environmentally friendly practices. With the shift in consumer preferences towards sustainable products, many businesses are trying to take advantage of this by projecting a positive image, but doing very little in practice. They do this in a variety of ways, like slapping “natural” or “sustainable,” terms without formal or legal definitions on product labels, or making vague and irrelevant claims. Greenwashing remains an issue, but with the rise of transparency and corporate reporting, it is becoming easier to identify and fix. Additionally, obtaining a third party verification helps businesses avoid this pitfall. While doing this can be a greenwashing tactic itself, a reputable organization will add credibility. These external certifications require firms to show the numbers, which also allows stakeholders and shareholders to dig into data themselves. Finally, more industries are creating trustworthy sustainability-specific associations that provide a form of third party verification and disseminate best practices.

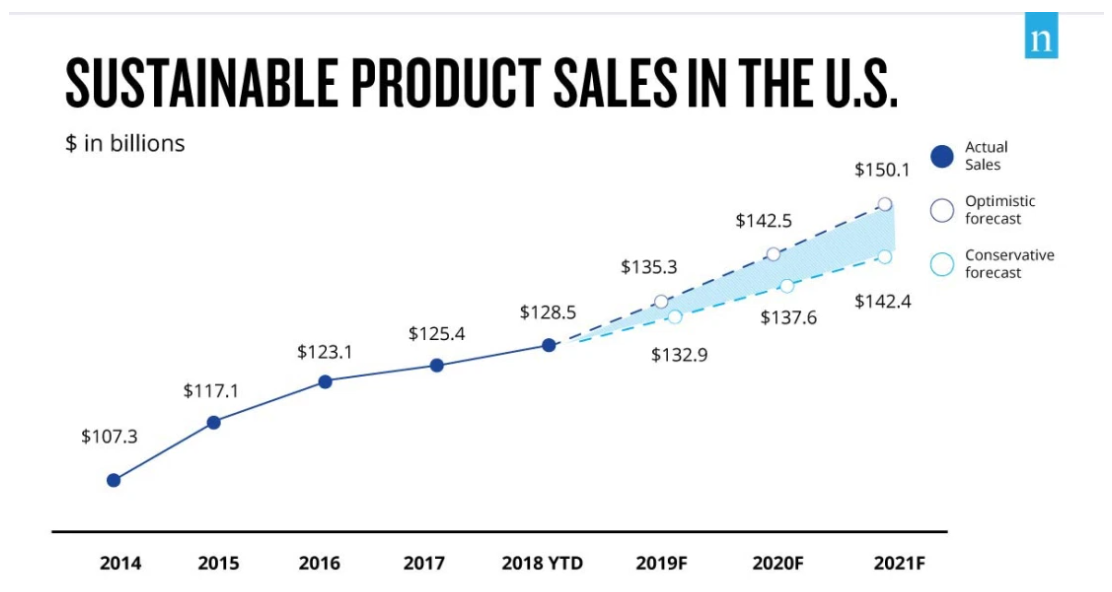

Historically, business leaders have been reluctant to embrace sustainability due to the upfront costs and long payback periods. Recently though, businesses are changing their practices due in part to consumers’ increasing desire for sustainable products, as well as a growing perception that a prosperous society is good for profits. As many as 75% of millennials, the largest growing consumer base in the world, say they are willing to pay more for sustainable products. Growth is the name of the game and businesses are becoming ever-more environmentally friendly to capture these eco-conscious consumers. In fact, sustainability-marketed products increased in sales by 30% and contributed over 50% of growth in consumer packaged goods (CPG) from 2013-18, with those numbers expected to trend even higher moving forward. As a result, Nielsen predicts that consumers will spend up to $150 billion on sustainable goods in 2021, an increase of $14-22 billion over 2018 spending. Businesses are realizing that they can either ride this wave by gaining market share from the rapidly-growing number of environmentally responsible consumers, or lag the market and peers by ignoring this trend.

Source: Nielsen (2018), Was 2018 the Year of the Influential Sustainable Consumer?Improving Sustainability in Supply Chains

There are two primary levers to improve the environmental impacts of a supply chain: improving sustainability internally within the supply chain, and holding external suppliers to a higher environmental standard. Possible areas of improvement internally include opting for renewable energy, improving energy and water efficiency, and reducing resource consumption. To directly enact change within a supply chain, a company must own or have control over the activities they wish to improve. Alternatively, companies can encourage or require their external partners to improve their operations when they cannot do so directly.

Renewable Energy

Incorporating renewable energy projects as part of a company’s supply chain efforts is gaining steam. Renewable energy has become the cheapest source of energy in most places as the cost of the technology has rapidly fallen, and new financing vehicles have improved access and lowered upfront costs. Switching to renewables also provides resiliency with price stability and mitigation of future regulatory risk. All of this will make companies more money than the status quo. For supply chain managers who emphasize being agile and having the ability to withstand external disruptions, these projects become even more attractive, as they provide cost and risk benefits across the supply chain.

Through the RE100 initiative, 263 of the world’s most influential businesses have committed to pursuing 100% renewable energy by at least 2050. There are a number of companies taking actions to reduce their emissions today. For example, by partnering with renewable energy developers, Anheuser-Busch, the largest beer company in the world, will begin acquiring 100% of its purchased electricity from renewable sources by mid-2021, and General Motors has committed to using 100% renewable energy by 2050. Other similarly impressive commitments have been made by companies like Walmart, Microsoft, and Apple.

Protecting the Local Environment

Reducing energy, water, and resource consumption from operations is both good in itself, and helps reduce GHG emissions. This occurs on a case-by-case basis for each company and is ultimately dependent on the capabilities of each company. Anheuser-Busch is an example of a company that has improved the sustainability of their internal supply chain by slashing resource consumption. As a CPG company that has verticalized the majority of its operations, Anheuser-Busch owns and operates farms, breweries, wholesalers, distribution centers, and a dedicated fleet of vehicles. Since Anheuser-Busch owns much of its own supply chain, it has greater control to enact change internally than some other companies.

Producing beer is a very water-intensive process, from watering crops to brewing, from to pasteurizing to shipping. Recognizing this fact, Anheuser-Busch is taking concrete actions to shrink its impact. Over the last ten years, Anheuser-Busch has reduced its water usage by almost 30%, saving 2 billion gallons of water since 2010, and has the goal of reducing it by another 9% in the next 5 years. This makes its operations more efficient, and is an obvious way to save money on both water and energy costs. In addition, Anheuser-Busch is going above and beyond to ensure that the watersheds in its communities stay healthy. In an increasing trend of corporations using “systems thinking“ to expand their reach and solve the root causes of problems, Anheuser-Busch is partnering with The Nature Conservancy to improve water quality and help meet the water needs of its communities. This is part of the company’s efforts to ensure that all its communities have measurably improved water availability and quality by 2025. It is part of a robust supply chain effort to mitigate the risk of AB’s water supply in high-stress areas — water availability and quality are quickly becoming two of the riskiest inputs to the brewing process as climate change and pollution continue to affect watersheds around the world. Pursuing environmental initiatives like this make business sense, and ensure that the company will continue to have the high-quality water it needs to produce its product, while also creating positive impacts in its communities.

AB’s initial environmental efforts focused on capturing easy gains available through state and national sustainability initiatives, and resulted in $420m of additional revenue and over $90m in savings. Retrofitting for LED lights, upgrading to LEED-certified buildings, and using EnergyStar appliances are all classic examples of “low-hanging fruit” that will improve the energy efficiency of any business. Supply chain managers also seek to limit the breakage, damage, and expiration of products because this leads to increased costs and waste. Doing so simultaneously reduces energy, water, and land usage to optimize costs because any unsalable product leads to more physical production and carbon-producing activities across the supply chain to compensate for the lost product. Finally, improving the efficiency of product manufacturing through efforts like Toyota’s plan to integrate recycled materials into the production of new vehicles, and General Motors’ commitment to reducing emissions associated with its thermal load will have significant environmental benefits.

Transportation and Logistics

Transportation and logistics is the process of getting resources, materials, and finished goods to the right place at the right time to keep the supply chain operating efficiently. These processes can be made more eco-friendly by using alternative fuels and electric vehicles, or by optimizing route efficiency. For instance, shipping company UPS, which controls the transportation routes of the drivers within its supply chain, instituted its iconic “no left-turns policy” in 2004. They determined that turning left across traffic results in a higher risk of accident and wastes time and fuel. To be more efficient, UPS chose to minimize left-hand turns, which has resulted in cost savings from eliminating 10m gallons of fuel and avoiding over 20,000 tons of carbon dioxide annually, demonstrating how supply chains and sustainability can work together toward the same goals. Other companies have since followed suit to optimize routes to be as efficient as possible to save time, money, and emissions.

When it comes to fuels, many companies will go through a progression of first switching to alternative fuels, and eventually to electric vehicles. Most immediately, renewable natural gas (RNG) is one of the most popular alternative fuels. RNG refers to methane captured from sources like landfill waste and biodigesters, and emits significantly less GHGs per unit of energy than conventional natural gas or gasoline. Recent studies estimate that America could produce enough RNG to displace nearly 25% of diesel fuel in heavy transportation. Additionally, green hydrogen will likely play a large role in this alternative fuel future. Many long-haul truck engines can run on hydrogen, and its high energy density makes it a perfect fit for long-distance transport. Green hydrogen can also use existing infrastructure (think: natural gas pipelines), and performs better than batteries for long-term storage in certain applications.

Finally, auto manufacturers are vowing to produce more electric vehicles and logistics companies are raring to buy them. The Tesla Semi is one of the latest product aimed at the sustainable logistics sector, having been announced in 2018. Companies like PepsiCo and Walmart immediately placed orders, while Anheuser-Busch recently purchased 840 zero-emission trucks from Nikola, with the goal of eventually shifting its entire dedicated transportation fleet to electric vehicles. As is the case with other sustainability initiatives, electric vehicles save on operating costs, since the cost per mile for electric vehicles can be as low as one-tenth that of typical diesel.

Targeting Suppliers’ Emissions

Companies like Anheuser-Busch and Walmart use their leverage and scale to persuade their suppliers to increase their environmental standards and efforts. The average company’s supply chain generates 5.5 times more GHGs than its own operating emissions. As companies and consumers realize this, more firms are focusing on requesting information and positive changes from their suppliers. According to the Carbon Disclosure Project, when purchasers push their suppliers to improve, it creates a cascading effect of sustainable practices all the way down the supply chain. However, those who fail to act may come to odds with their customers’ expectations and see their financials suffer as a result.

One method that companies can use to invoke sustainability in their suppliers is through the procurement of intermediate goods, which is the process of deciding where to buy things which will be used to create a final product. This happens in different ways depending on the company and product. Walmart has committed to sustainable textile sourcing for its clothing lines which will partially contribute to cutting 93m metric tons of carbon emissions. Another initiative to reduce carbon emissions through intermediate good procurement is Anheuser-Busch’s partnership with a new “low-carbon” aluminum can supplier that uses hydroelectricity. Further, Starbucks is making a concerted effort to purchase sustainably-sourced goods for everything it uses, from sustainable aprons for their baristas, to the furniture in their cafes. Leading Japanese cosmetics company KAO and UK logistics organization Network Rail are also encouraging their suppliers to reduce their carbon emissions and create sustainable products. As a result, over 80% of KAO’s suppliers have set their own emissions reduction targets, and Network Rail’s suppliers are finding creative solutions and developing best practices. The ability to purchase environmentally-friendly products is tethered to the availability of these products, which is why it is important that corporations encourage suppliers to produce sustainable products.

Another method of leveraging suppliers to drive sustainable change that is available to retailers is through the procurement of final goods. In one of the most impactful cases of a company doing so to create a more sustainable future, Walmart is leaving its bad reputation behind, and creating a structure of environmental sustainability for its over 3000 suppliers worldwide. As the largest company by revenue in the world, they have the ability to create their own supplier structure. Walmart is doing so through Project Gigaton, its initiative to eliminate one billion metric tons of carbon emissions from their supply chain by 2030. Project Gigaton encourages suppliers to create or advance their sustainability initiatives in order to become a “preferred supplier,” which enables companies to earn recognition and gain access to Walmart’s sustainability resources and tools. Being a supplier for Walmart is a unique and profitable relationship, and Project Gigaton has made it an environmentally sustainable relationship as well.

Walmart has also partnered with Hongkong and Shanghai Banking Corporation (HSBC), a leading international bank, to create financial incentives for suppliers who upgrade their sustainability performance. Suppliers who do so will receive improved financing from HSBC, as well as cost savings. Most importantly, they can expect business growth as they pursue sustainability efforts. By embedding sustainability in the global supply chain and rewarding those who pursue it, Walmart has set procurement standards that drive sustainability in a meaningful fashion. Partnerships like this between such impactful companies create truly positive frameworks that will deliver real reductions in carbon emissions due to the size and control of their respective marketplaces.

Impacts of COVID-19

The COVID-19 crisis has forced supply chain leaders to focus on short-term priorities in 2020, implementing agile responses to global disruption. It has had painful effects on businesses — 47% of large corporations anticipate budget cuts for their sustainability initiatives due to the pandemic’s financial impacts. Unfortunately, this will force sustainability initiatives to be sidelined or modified until businesses can return to normal, setting back companies in pursuit of their sustainability goals. Moreover, the pandemic has disrupted previous assumptions in supply chain management, and highlighted the need for supply chain resiliency and robustness. For instance, many supply chain managers are now reevaluating their assumptions about just-in-time delivery, sourcing redundancy, and consumer preferences. The crisis has underscored the need to broaden and accelerate efforts to increase visibility, flexibility, and responsiveness to unexpected shocks.

The good news is that many resiliency efforts are aligned with continued momentum for sustainability in other ways. Supply chain managers understand that now is not the time to pause sustainability efforts — longer-term, systemic threats will still be there once this disruption eases, along with consumer pressure to solve them. Enhancing resilience and robustness includes identifying concerns in locations particularly vulnerable to climate change; installing renewable sources of energy to provide price stability, a reliable energy supply, and decreased operating costs; and improving responsiveness by moving towards measures of real-time performance through the use of various technologies like drones, sensors, and blockchain. All of this indicates that while there may be some tradeoffs between efficiency and robustness in the short-term, there are many areas where robustness reinforces sustainability in the long-term. The COVID-19 pandemic has illustrated that supply chains are ingrained in wider economic, environmental, and social contexts. This helps develop a systemic view, in which supply chain managers must link performance metrics to external reference points such as climate change, water usage, or a global pandemic.

Conclusion

Companies up and down supply chains are now helping to create a better, more sustainable future. That future is looking brighter every day as a result. The previous notion that sustainability is bad for business is beginning to change, as consumer companies have come to appreciate the extent to which their supply chains contribute to global sustainability challenges, as well as the effects that poor sustainability management can have on their growth and profitability. Many leading consumer businesses have created a widening array of practices and tools for working with their suppliers to lessen sustainability impact and have begun to realize the benefits of their efforts. Their experiences illustrate the possibilities for many more companies to initiate similar activities. Companies that manage their supply chain impact will be positioned to gain from the boom in consumer spending that is expected to take place over the next decade and beyond.

The future of sustainability in supply chains is happening now. Companies like Walmart and Anheuser-Busch are using AI paired with big data in their everyday operations. These same functions will provide transparency along the entire supply chain, and enhance sustainability efforts. Moreover, they will offer enhanced visibility to determine opportunities for improvement and the ability to quickly spot and solve issues in real time. PricewaterhouseCoopers, a consultancy, estimates that AI can add over $5 trillion to the world economy in the next decade by improving decision-making in environment-related sectors alone. The use of AI can improve forecasting and better estimate quantities of goods for ordering, reducing waste. This decreases the risk of that products must be thrown away due to seasonal trends and expiration, and will also optimize transportation. All of this serves to simultaneously save companies money, and improve their carbon footprints.